DRAGON

pellet - fired central heating boiler

Central heating furnaces

Central heating boilers of DRAGON type are low-temperature ecological central heating boilers designed for efficient and fully- automated combustion of biomass in pellet form. In the central heating boiler a self-cleaning burner is used, along with a highly technologically advanced controller.

Advantages

- STEEL OF THE HIGHEST QUALITY – boiler sheets P265GH

- EASIEST ACCESS TO LOADING – fuel storage tank placed at the height of 1 m above the ground

- ECOLOGICAL FUEL – a pellet boiler with an option to burn eco-peas / coal dust (30 mm)

- MOST CONVENIENT TANK LOCATION - the option to configure from both the left-hand and right-hand side of the boiler

- SIMPLEST CLEANING OF THE BOILER – access to channels by opening the front door

Fuel type:

pellet

pea-coal/pellet

fine coal/pellet

Central heating boilers DRAGON are produced with the capacity of 30 kW. The main advantage of DRAGON central heating boilers is comfortable and very easy operation, practically reduced to periodical fuel filling in the intake hopper (every 3 - 6 days depending on weather conditions and the level of building is insulation).

DRAGON central heating boilers are constructed in order to enable attachment of an external fuel feeding system providing fuel from main storage room. Regular maintenance includes scheduled emptying of the ash pan.

The universality of these central heating boilers consists in the possibility of a fuel tank (hopper) installation both on the left and the right side.

The innovative auto- inflammation system and automatic burner cleaning system enable burning of lower quality (dirty), low-priced fuels. Therefore, the DRAGON central heating boilers have been recognized as the most economic and most environmentally- friendly central heating boilers in their class.

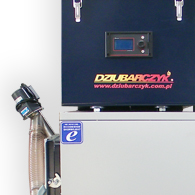

| Detailed list | Technical specifications of DRAGON | |||||||||||

| Type | DRAGON | |||||||||||

| Rated power | kW | 30 | ||||||||||

| Power range | kW | 10 - 30 | ||||||||||

| Heating area | m² | 80 - 250 | ||||||||||

| Thermal efficiency | % | 91% | ||||||||||

| Maximum water temperature | °C | 90 | ||||||||||

| Minimum temperature of return | °C | 35 | ||||||||||

| Maximum working pressure | Bar | 1,5 | ||||||||||

| Fuel consumption | kg/h | 3,5 | ||||||||||

| Chimney hole diameter | cm² | 280 | ||||||||||

| Height of chimney | m | 5 | ||||||||||

| Water storage capacity | l | 100 | ||||||||||

| Filling up hopper capacity | kg | 150 | ||||||||||

| Fuel | - | pellet (biomass) | ||||||||||

| Flue diameter | mm | ø160 | ||||||||||

| Diameter of supply and return connecting pipe | cal | 1" | ||||||||||

| Overall weight without water | kg | 275 | ||||||||||

| Overall dimensions: - width D - height H - depth G - height to the center of flue |

mm |

1150 1500 780 830 |

||||||||||

|

Overall dimensions - exchanger: - width - height - depth |

mm |

800 880 430 |

||||||||||

|

Filling up hopper dimensions: - width - height - depth |

mm |

600 1150 730 |

||||||||||

| Power consumption | W | 35 | ||||||||||

| Supply voltage | V | 230 | ||||||||||

| Clearance on store tank side | mm | 550 | ||||||||||

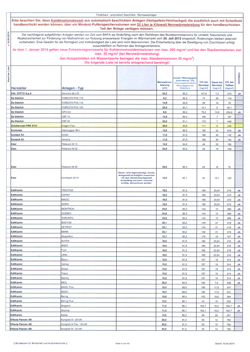

Control device RK-2006LP

The RK-2006LP controller is a device used to control the temperature of the pellet-filled boilers.

The level of the temperature of the boiler is kept at the level set by the user by controlling the blowing fan and the feeding screw or the dosing feeder co-operating with the built-in internal feeder (stoker). The controller makes it possible to control the central heating circulation pump and the domestic hot water pump. The controller also has a function of automatic fuel ignition.

The LCD text display allows a simple, intuitive operation. A wide range of functions allowing programming the parameters of the controller allow a precise adjustment of the parameters of the boiler operation in accordance with the heating system.

The controller is equipped with STB - independent electronic protection of the boiler against overheating.

In order to guarantee a more precise control of the temperature of the heated rooms, the controller has been equipped with an input making it possible to connect any room thermostat with an output switch.

The casing of the controller is adjusted to the standard dimension of 144 x 96 mm.

The controller is adequately equipped with a secured semiconductor temperature sensors.

Boiler configurations

In the advanced boiler configuration we offer a few options:

- we offer a selection of the location of the feeder from the left-hand / right-hand side of the boiler

- we offer a selection of opening the door to the left / to the right

- we offer a selection of the diameter and kind of power and return connectors

- we offer a selection of the location of the power and return connectors

- we offer a selection of the shape and location of the boiler flue, e.g. elbow to the left, to the top etc.

1. The output of the flue

at the back in the middle.

2. The output of the flue

at the back (the elbow to the left).

3. The output of the flue

at the back (the elbow to the right).

The shape of the flue

The shape of the flue can be selected in accordance with the customer’s expectations. We offer the circular shape / the square shape / the rectangular shape.