Technology

CAD DESIGN

We have an engineering and design office where we perform professional and comprehensive service of computer-aided CAD design.

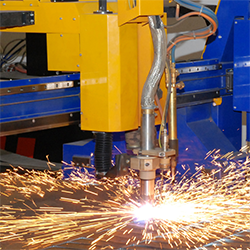

PLASMA CUTTING

We cut boiler sheets with the use of state-of-the-art plasma cutters. Thanks to using this technology we are able to reduce the majority of the welds – even by 60%, which translates into the durability of the boiler. The plasma cutter burns the whole casings which are then bent with a bending machine.

SHEET BENDING

The bending machines which we use satisfy the highest demands in terms of technology, speed, precision and production repeatability. Specialized equipment makes it possible for us to produce parts of the boiler with elimination of unnecessary welds thanks to which we achieve a more effective production speed.

MIG/MAG AND TIG WELDING

The highly qualified team of welders have MIG/MAG and TIG welders at their disposal, which makes it possible for us to obtain the joints of the highest quality in the boiler.

POWDER COATING

It is performed at the end of the production. Apart from aesthetic qualities, it has many advantages, among other things – smooth coating without any cracks or damp patches, resistance to mechanical damage, thermal and anticorrosion resistance, 3 RAL colour palettes (blue / green / red).

QUALITY CONTROL

Before the boiler is placed in one of the storage facilities, a thorough quality control is performed and what is taken into account is dimensions, precision of the coating, tightness of the welds, work of all the elements of the boiler, work of the controller; we also make sure that the boiler is well prepared for transportation.